Contact Us

- No. 335 Jinyang Road (No. 2 Jinxia Road), Lujia Town, Kunshan City , Jiangsu Province, China.

- Cell phone: +86-13775288830

- E-mail: info@yuncogroup.com

Kunshan Yunco Precision Co., Ltd. is a high-tech enterprise specialized in research, development, production, sale and after-sale services for laser micro-processing system, precision measuring system, precision automation system and key functional modules, as well as processing of high-end equipment.

It was established in Kunshan in July 2012 by technology talents from Huazhong University of Science and Technology, Wuhan University of Technology, Hefei University of Technology and Changchun University of Science and Technology, etc. The industrial park is now located at No. 335 Jinyang Road (No. 2 Jinxia Road), Lujia Town, Kunshan, covering an area of 25 mu. It is comprised of the Laser Intelligent Equipment Manufacturing Division, Precision Photo-Electric Technology Application Division, Innovative Service Platform for High-end Manufacturing System of Medical Equipment and other departments. It sets up an office in Southern China (Dongguan) to provide sale and after-sale services for laser micromachining system and processing services for high-end equipment. It now has more than 120 employees.

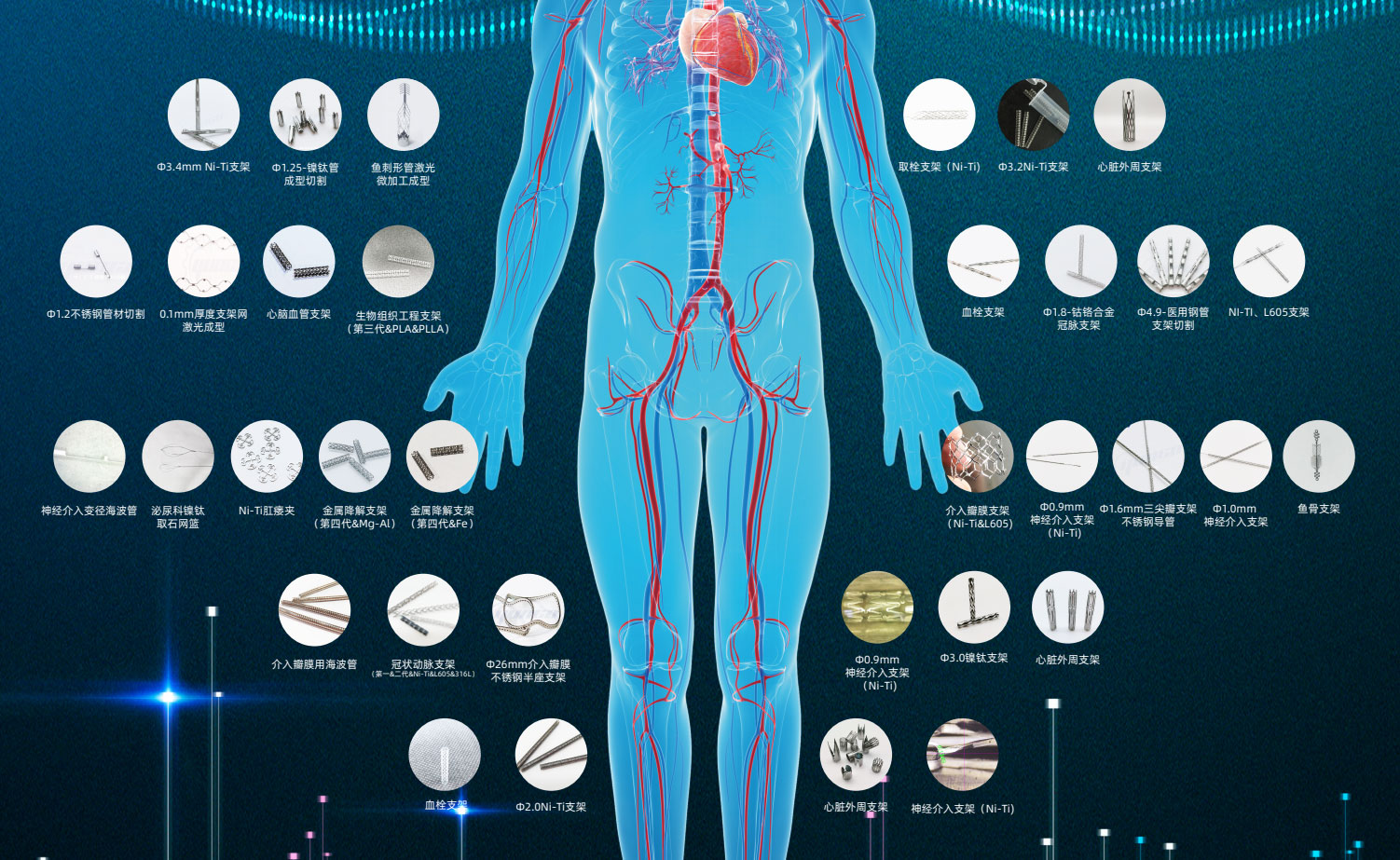

Driven by independent innovative technology, Yunco Precision has obtained multiple patents on optical, mechanical and electronic integrated precision system and technology application. It provides laser micromachining and innovative service system solutions for such fields as medicine, electronic industry, automobile industry, aviation, military industry, and hardware for daily use. It has won a series of honors, such as National High-tech Enterprise, Jiangsu Technology-based Private Enterprise, Suzhou Research Center for Precision Manufacturing System and Process Engineering Technology for Medical Equipment, Kunshan Science and Technology R&D Center and Kunshan Professional, Fine, Unique and New Enterprise. With quality system certification such as ISO9001, IATF6949 and ISO13485, it is a solution provider for laser micro-machining system and an innovative service integrator.

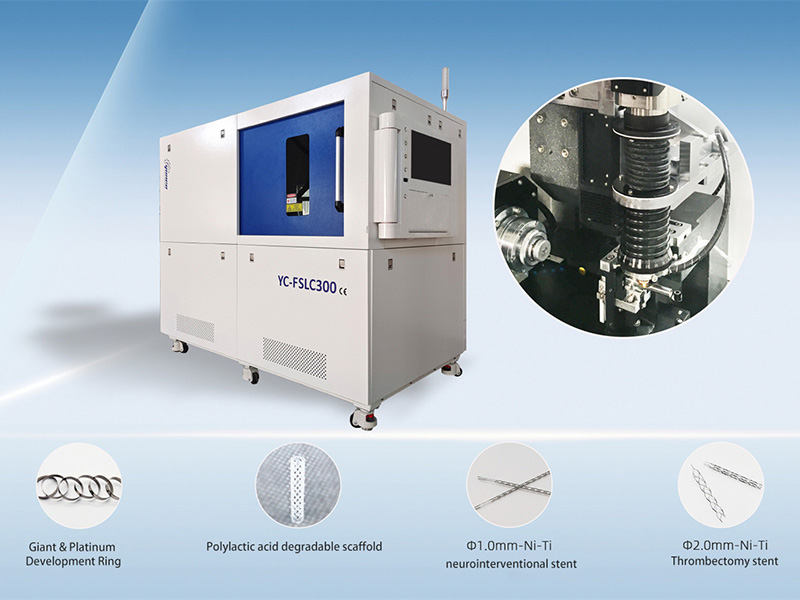

Our machines boast high precision with a cutting seam width ≤ 20um and width consistency of ≤ ± 5um, ensuring detailed and accurate cuts.

Yes, our versatile machines can process a range of materials, including metals like 316L, Ni-Ti, L605, and non-metals like PI.

Built for longevity, our machines feature robust construction and quality components, ensuring long-term reliability.

Our machines are user-friendly, with self-developed software that is more convenient and simpler than German software, offering a clearer interface. Comprehensive training and support are provided for effortless operation and maintenance.

Designed for optimal speed and efficiency, our machines are the fastest in the industry while ensuring precision. This is due to our self-developed software and key functional components that offer better compatibility.

We provide prompt and efficient technical support to address any issues or queries.

Customization options are available to meet specific production needs, ensuring optimal performance. We also offer services to repair other brands' stent laser cutting machines and upgrade old machines to new.

Safety is paramount. Our machines include features like laser protective glass and emergency stop functions to protect operators.

For standard machines, production can start immediately after unboxing and plugging in. For custom machines, our after-sales team will visit the site for installation and training, with timelines tailored to client needs.

We have supplied our machines to notable manufacturers like MicroPort, Lepu Medical, Meril, Relisys, and more.