Contact Us

- No. 335 Jinyang Road (No. 2 Jinxia Road), Lujia Town, Kunshan City , Jiangsu Province, China.

- Cell phone: +86-13775288830

- E-mail: info@yuncogroup.com

High precision machining

. Accurate positioning: Positioning accuracy <0.01mm (precision customized jig achieves precise axial & radial positioning of snake bones)

. Precise lamination: Repeated lamination accuracy <0.01mm (machine vision automatically corrects the lamination position & lamination displacement closed-loop control)

. Online detection: supports online monitoring & detection of the pressing process and status

. High pressing efficiency: the automatic pressing process of a single snake bone is completed within 30 seconds

Strong adaptability

. Compatible with automatic lamination processing of endoscopic cobra bone threading rings of different materials & tube shapes & tube diameters & tube lengths

. High degree of automation, supporting automatic lamination processing of two-way & four-way & eccentric wire threading rings

. Equipped with self-developed automatic lamination control & machine vision positioning software system

Flexible design

. Follow the ergonomic design concept, exquisite and simple

. Modular design, can be incorporated into the endoscopic cobra bone laser cutting machine to form an endoscopic cobra bone fully automatic production line

. Support software and hardware system & function configuration & customized design of intelligent production management

. Easy to operate & intuitive interface

Technical parameters

| Maximum operating speed |

100mm/s (X); 20mm/s (Y); 10mm/s (Z); 100rpm (θ); |

|

Positioning accuracy |

±10um(X);±10um(Y);±10um(Z);&# 177;50arcsec(θ); |

|

Repeat positioning accuracy |

±5um(X);±5um(Y);±5um(Z);&# 177;30arcsec(θ); |

|

Repeat pressing accuracy |

<0.01mm; |

|

Processing material |

304, 316L, Ni-Ti, L605 and other alloys; |

|

Laminated product length |

0~200mm (longer supports can be customized); |

|

Clamping pipe range |

Φ1.0~Φ16.0±0.02 mm; |

|

Lamination material wall thickness |

0~0.5±0.02mm; |

|

Power supply |

220V±10%, 50Hz; AC 15A (main circuit breaker); |

|

Device dimensions |

1200mmx1200mmx1700mm; |

|

Device weight |

800Kg; |

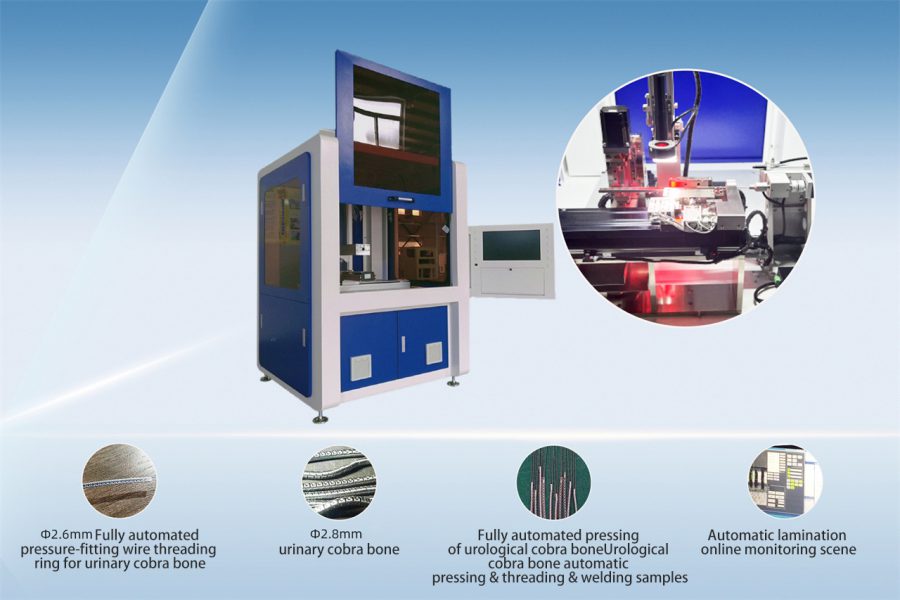

Sample display