Contact Us

- No. 335 Jinyang Road (No. 2 Jinxia Road), Lujia Town, Kunshan City , Jiangsu Province, China.

- Cell phone: +86-13775288830

- E-mail: info@yuncogroup.com

High precision machining

. Small cutting slit width: <20um

. High processing accuracy: ≤±5um

. Good cutting quality: infrared & green light processing modes are available, no burrs & smooth cutting & minimal heat affected zone

. High processing efficiency: cutting through one side of the pipe wall at one time & continuous automatic feeding processing

Strong adaptability

. Possessing fine processing technology capabilities such as laser dry cutting & wet cutting & drilling & blind groove digging of precision thin-walled tubes

. Can process 316L&Ni-Ti&L605&Fe&Mg&Zn&PLA&PLLA& &PI&nylon&glass and other metal & non-metal materials

. Compatible with precision thin-walled tube clamping systems such as precision D-type chucks & ER series chucks & three-jaw chucks

.Using a combined precision thin-walled tube bushing support system that adapts to shape tolerance changes

. Provide supporting solutions such as continuous automatic feeding processing of precision thin-walled tubes & wet and dry cutting, sealing and splicing.

. Equipped with self-developed laser micromachining 2D & 2.5D & 3D CAM software system

Flexible design

. Follow the ergonomic design concept, exquisite and simple

. Configure a machine vision system to monitor the laser dynamic processing process online in real time.

. Closed optical path system & precision laser cutting head design, stable and reliable

. Flexible combination of software & hardware functions, supporting personalized function configuration & intelligent production management

.Support forward innovative design from component level to system level

. Open control & laser micromachining software system is easy to operate & intuitive interface

Technical Parameters

|

Maximum operating speed |

500mm/s (X); 100mm/s (Z); 600rpm (θ); |

|

Positioning accuracy |

±1um(X);±3um(Z);±15arcsec(θ); |

|

Repeat positioning accuracy |

±0.2um (X); ±1um (Z); ±3arcsec (θ); < /p> |

|

Cutting seam width |

15um~25um; |

|

Rebar width consistency |

<±5um; |

|

Processing material |

316L&Ni-Ti&L605&Fe&Mg&Zn&PLA&PLLA& &PI&nylon&glass and other metal & non-metal materials; |

|

Pipe blank length |

<2.5m (longer lengths can be customized); |

|

Processing wall thickness |

0~0.5±0.02 mm; |

|

Clamping pipe diameter |

Φ0.1~Φ7.5±0.02 mm&Φ0.3 ~Φ16.0&# 177;0.02 mm&Φ1.0 ~Φ30.0±0.02; |

|

Single processing range |

0~300mm (longer products will be processed by segmented splicing); |

|

Laser type |

Infrared & green femtosecond laser; |

|

Laser wavelength |

1030nm~1070nm± 10nm&532nm±10nm; |

|

Laser power |

10W&16W&20W for selection; |

|

Power supply |

220V±10%; 50Hz; AC 25A (main circuit breaker); |

|

Compatible file formats |

DXF, DWG; |

|

Device dimensions |

2100mmx1250mm (1000mm)x1750mm; |

|

Device weight |

1800Kg; |

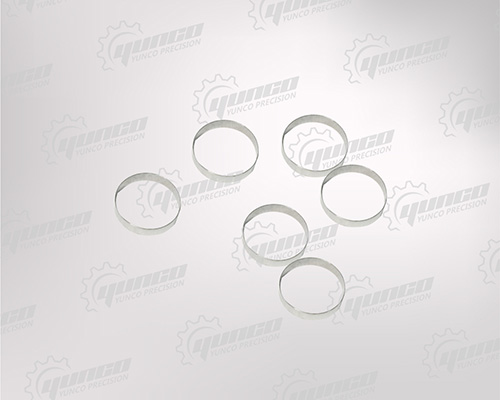

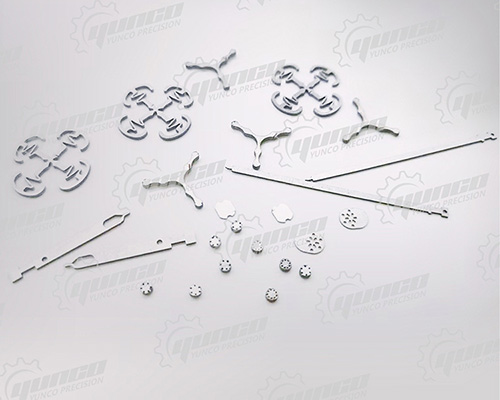

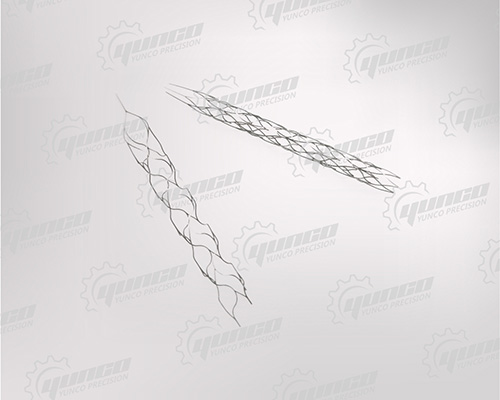

Sample Display