Contact Us

- No. 335 Jinyang Road (No. 2 Jinxia Road), Lujia Town, Kunshan City , Jiangsu Province, China.

- Cell phone: +86-13775288830

- E-mail: info@yuncogroup.com

High precision welding

. Small welding spot: <Ø200um

. High welding precision: radial runout of pipe equipment during rotation <10um

. Good welding quality: smooth weld surface, no obvious deformation & bumps & pits & discoloration, good stability

. High processing efficiency: pneumatic automatic control is used to achieve precision thin-walled pipe clamping, and it is compatible with automatic pipe loading and unloading systems

Strong adaptability

. Configure precision visual positioning and monitoring system for processing process

. Can perform fine welding processing on equal diameter pipes & deformed pipes & semi-finished pipes & flat instruments

. Can process stainless steel & nickel titanium & platinum iridium & tantalum & cobalt base & aluminum & copper and other alloy materials

. Diversified combined precision tube automatic clamping system

. Equipped with self-developed laser micromachining 2D & 2.5D CAM software system

Flexible design

. Follow the ergonomic design concept, exquisite and simple

. Configure a machine vision system to realize automatic positioning and real-time online monitoring of the laser dynamic processing process

. Flexible combination of software & hardware functions, supporting personalized function configuration & intelligent production management

.Support forward innovative design from component level to system level

. Open control & laser micromachining software system is easy to operate & intuitive interface

Technical parameters

| Maximum operating speed |

50mm/s (X); 50mm/s (Y); 50mm/s (Z); 500rpm (θ); |

|

Positioning accuracy |

±5um(X);±5um(Y); ±5um(Z);±25arcsec(θ ); |

|

Repeat positioning accuracy |

±3um(X1);±3um(Y);±3um(Z);±10arcsec(θ ); |

|

Welding spot |

Φ100um~Φ300um; |

|

Processing material |

Stainless steel & nickel titanium & platinum iridium & tantalum & cobalt base & aluminum & copper and other alloy materials; |

|

Processing wall thickness |

0~1.0±0.02 mm; |

|

Pipe processing range |

Φ0.1~Φ7.0±0.02mmΦ1.0~Φ16.0±0.02 mm available Select; |

|

Planar processing range |

300mm*300mm; |

|

Processing range |

0~300mm; |

|

Laser type |

Fiber laser; |

|

Laser wavelength |

1030~1070nm±10nm; |

|

Laser power |

80W&100W&200W&300W&QCW150W for selection; |

|

Single pulse maximum energy |

50J; |

|

Laser welding frequency |

1-20Hz; |

|

Laser welding depth |

0.1-1.0mm; |

|

Pulse width |

0.1-20ms; |

|

Power supply |

220V±10%, 50Hz; AC 15A (main circuit breaker); |

|

Compatible file formats |

DXF, DWG; |

|

Device dimensions |

1200mmx1300mmx1750mm; |

|

Equipment weight |

800Kg; |

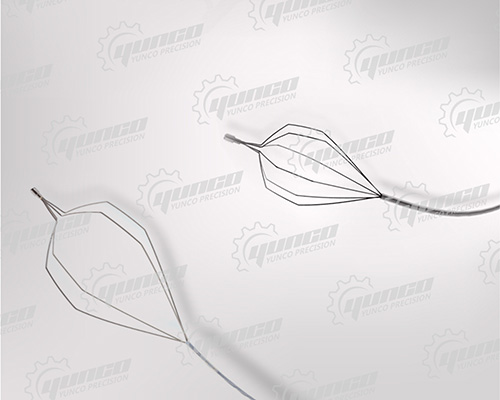

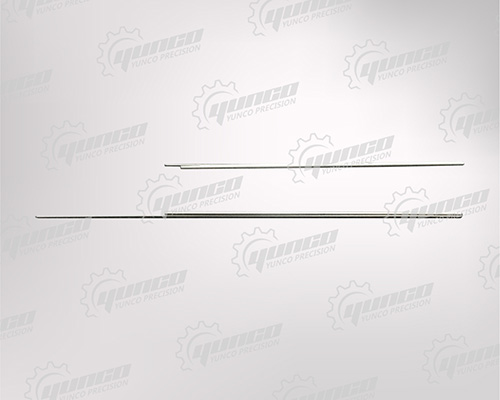

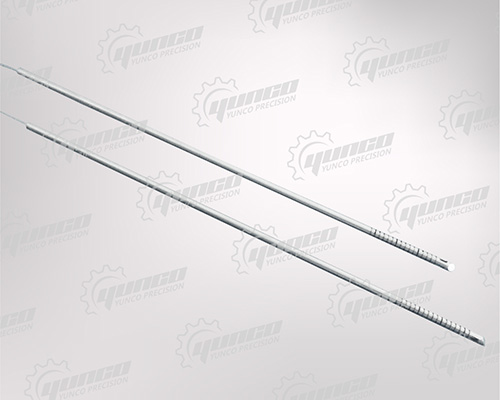

Sample Display